Zimbabwe has rich nature resource, that is the bottom of agriculture and business. The output value of industry accounts for 2/3 of the total industry and agriculture output value. The general economic development level of Zimbabwe is simply second to South Africa and manufacturing, mining and agriculture would be the 3 greatnesses mainstay industry. Zimbabwe is really a landlocked country in southern Africa.

Zimbabwe has rich nature resource, that is the bottom of agriculture and business. The output value of industry accounts for 2/3 of the total industry and agriculture output value. The general economic development level of Zimbabwe is simply second to South Africa and manufacturing, mining and agriculture would be the 3 greatnesses mainstay industry. Zimbabwe is really a landlocked country in southern Africa.

Zimbabwe is wealthy in mineral resources such as gold, chrome, asbestos, corundum along with other minerals producing country in the world. Now, Zimbabwe??£¤s commercial exploitations is much more than 40 kinds of minerals including gold, chrome ore, nickel, asbestos, coppers and coal and so on.

Zimbabwe mining equipments

Zimbabwe is abundant in natural resources such as coal, chromium, iron ore, asbestos, gold, silver, lithium, niobium, lead, zinc, tin, uranium, copper, nickel, etc. SBM can supply you related mining equipments such as coal crusher, coal mill, iron ore crusher, asbestos ore mining equipment, gold crusher, silver ore crusher, lithium mining equipment in Zimbabwe, niobium ore grinders, lead crusher, zinc crusher, copper ore crusher, nickel ore grinders etc.

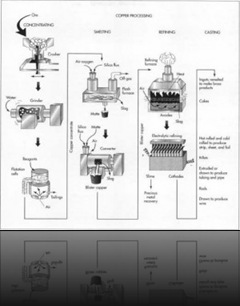

Zimbabwe copper ore mining equipment

Zimbabwe mining industry has a new hotspot in recent years within the diamond or gold mining simply because the CIDA Number of Canada produced a completed throughout Zimbabwe showing an encouraging gold or diamond deposits.

Copper ore could possibly get from native copper ore, chalcopyrite, chalcocite, azurite, malachite, and so on. Copper ore mining equipment is used widely in copper ore crushing procedure, copper ore grinding procedure etc. Copper ore crusher takes because the primary crushing equipments, following copper ore crushed, they conveyed by belt conveyors enter grinder equipments such as copper ball mill, copper ore vertical mill etc. Following coarse grinding, roughing, copper ore flotation, and copper ore choice, we can get the fineness copper goods.

Zimbabwe grinding mill equipments

Zimbabwe grinding mill equipments consists of ball mill, Raymond mill, vertical mill, trapezium grinding mill and so on applied widely in Zimbabwe mining industries like lithium minerals processing plants, gold mining industry, chromium ore mining, chromites ore mining Zimbabwe, silica sand production lines, coal crusher plant in Zimbabwe and so on. Also we can supply jaw crusher, Zimbabwe cone crusher, Zimbabwe mobile crusher, hammer crusher and so on for crushing ore materials in ore crushing plants or quarry plants.

Stone crusher in Zimbabwe

Stone crusher is designed to decrease large rocks into smaller rocks, gravel, or rock dust. Crusher machines might be used to reduce the dimensions, or change the shape, or to decrease the size of a solid mix of raw materials, of waste supplies so they can be more easily discarded or recycled, so that bits of different composition may be differentiated.

SBM is a expert manufacturer of mining crusher machine and industrial grinding mills, sand washer etc. We has formed a complete production-chain that takes crushers and mills as the primary products and vibrating screen, vibrating feeder, and so on. as supplementary products.