There’s scarcity of natural sand as a result of heavy demand in growing construction activities which forces to obtain the suitable alternative to sand. The lowest priced as well as the easiest method to getting alternative to natural sand is by crushing gemstone to get artificial sand of desired size and grade which would get rid all impurities.

The benefit of using good river sand is it mixes easily with concrete and bonds well, making the plastering work less cumbersome for that masons and giving a good finish for the buildings. But however, the continuous mining of sand causes environmental problems.

The benefit of using good river sand is it mixes easily with concrete and bonds well, making the plastering work less cumbersome for that masons and giving a good finish for the buildings. But however, the continuous mining of sand causes environmental problems.

In this scenario, artificial sand can be regarded as a welcome alternative to natural sand.

SBMhas hit upon the idea of designing a kind of sand making machine in order to making sands from many different types of stones . The artificial sand will be for sale in two grades – 1-3 mm for plastering and 3-5 mm for many construction work. As it would be double-washed and silt-free, it could bond better with concrete and would require lesser curing time than river sand.

Sand Making Process

Sand making machine is utilized in making artificial sand or manufactured sand as opposed to natural sand, from stones or rocks. Inside the sand making plant, it really is combined with other sand crushing machine in fine and medium size crushing of rocks, stones, minerals for building sand, aggregate and concrete. FOX Sand making machines are of high quality and powerful crusher, low in maintenance and operating cost.

The ultimate artifical sand is cubic with grounded edges. Artificial sand and aggregate is utilized in preparing good quality concrete for building and construction purpose, therefore the sand particle has to be equiexed cuboidal and glommed edges.

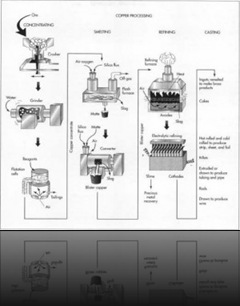

Sand Process Flow Chart

Regarding to detailed condition, 2 kinds of techniques usually are adopted in producing manufactured sand, dry way and wet way. Both ways can produce high quality manufactured sand as concrete aggregate. Especially, the dry way can produce not just the manufactured sand found in road surface, but the powder utilized in asphalt concrete.

Manufactured Sand Processing Flow Chart

1. Material Hopper

2. Vertical Shaft Impact crusher

3. Vibrating Screen

4. Sand Washer or Powder Separator

The feature with the processing:

1. As a result of VSI Series Vertical Shaft Impact crusher crushing principle, the shape of manufactured sand is cubic.

2. The rank of manufactured sand is affordable, and fineness modulus is adjustable.

![quartz-sand-equipment[1] quartz-sand-equipment[1]](http://lh4.ggpht.com/-yr6WWvaL8VM/TucmoMuc82I/AAAAAAAAAXU/KkrFiBR4zkk/quartz-sand-equipment%25255B1%25255D%25255B5%25255D.jpg?imgmax=800)

![chrome-ore-crushing-plant-in-South-Africa[1] chrome-ore-crushing-plant-in-South-Africa[1]](http://lh5.ggpht.com/-cwREWnXuGTY/TuBtYq0K-NI/AAAAAAAAAW8/pF2Ujcw2rkc/chrome-ore-crushing-plant-in-South-Africa%25255B1%25255D%25255B5%25255D.jpg?imgmax=800)

![Tanzania-80100tons-coal-crushing-plants[1] Tanzania-80100tons-coal-crushing-plants[1]](http://lh4.ggpht.com/-ywoKClzF2qk/TtxopWve_zI/AAAAAAAAASk/kXSLUxm3jr8/Tanzania-80100tons-coal-crushing-plants%25255B1%25255D%25255B12%25255D.jpg?imgmax=800)