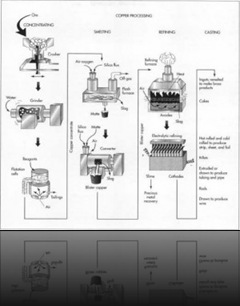

copper processing

South Africa is a Copper-producing Country. South Africa is the world’s second major manufacturer of copper ore,gold, and still is loaded with lots of other precious metals to supply. It is the world's main producer of manganese, chrome, platinum, vermiculite and vanadium. South Africa also has the title of becoming the third largest coal exporter on earth. South Africa is involved in the following commodities : Copper, Cobalt, Lead, Gold, Nickel, Silver, PGM, Uranium Oxide and Zinc (amongst others).

Copper Mining Equipment in South Africa

Each one of these precious and common metals that Nigeria produces originates from extensive money and time allocated to mining, which requires mining equipment. The mining equipment in Nigeria is equivalent to that used all over the world. The equipment needed is dependent a great deal on mining techniques. Surface mining is less harmful and complex than subsurface or subterranean mining, and for that reason is commonly less costly. The kind of mines also matter greatly when it involves identifying which kind of mining equipment may be needed. Placer deposits make reference to mines in which the valuable minerals are based in the sands or gravel on the top of ground or in the banks of rivers, streams or streams. Lode deposits are mines in which the valuable minerals are located deep within the veins of other rocks. Both these kinds of mines require surface mining in addition to subterranean mining techniques.

Copper Beneficiation in Copper Processing Crusher Plant

Copper flotation: general use easy process, over time of grinding, fine -200 mesh about 50% to 70%, 1 toughing, two or three occasions selected, one or two occasions sweeping election . Disseminated copper minerals, for example relatively small size, may think about the stages of grinding and separation process.

Treatment place copper concentrator, they will use rough concentrate regrinding – selected selection stage grinding process, and it is essence is mixed – flotation process. First with a coarse, rough election, sweep the election, after which grinding mill after which rough Concentrate selected by high-grade copper concentrate while focusing. Walk out of crude makes up about about 45% -200 mesh 50% -200 mesh after which carefully walk out about 90% to 95%.

No comments:

Post a Comment